How the DrylinePro Fixing works

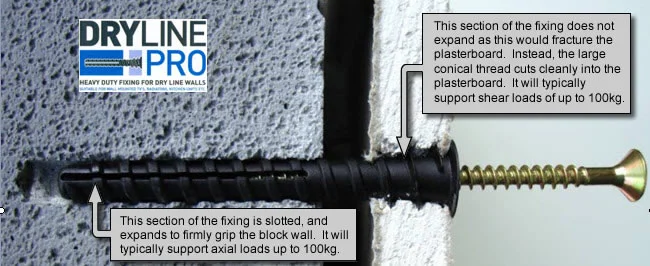

As a dry line wall has two parts – the block wall, and the plasterboard, the DrylinePro™ fixing has two ways of gripping. One is ideal for the block, the other ideal for the plasterboard.

Technical Note: The lower fixing on a shelf or TV bracket is often ‘under compression’ – it is being pushed back into the wall. The DrylinePro™ fixing is designed to take this type of load too without loading and damaging the plasterboard.

DrylinePro™ is a registered trade mark and the concept is protected through various patents.

Testing DrylinePro

Loading a Shelf with 200kg

This is the simple way to test DrylinePro™ fixings.Eleven 19kg blocks are loaded onto one shelf, that is fixed to a dryline wall with only 4 DrylinePro™ fixings (that is 2 fixings in each of the two shelf bracket).A simple but effective test.We did some more formal testing as well (see below).

Test Equipment

This shows our test rig for testing individual fixings for axial (pull out) load. An electronic load cell continuously measures the load while we apply load to a single fixing and record the process on a laptop.We test the system with a 20kg weight before testing the fixing to check the calibration of the load cell.The load cell and 20kg weight are calibrated to national standards.

Test Results

The typical load a single fixing can take is 100kg. The shear load and axial load capability being broadly similar. The actual load will depend on the type of block used with a typical range from 80 to 150kg maximum load on one fixing. Of course, we would never recommend that any fixings, including ours, be used to there extreme load capacity. Always leave a comfortable margin.For comparison, a typical fixing that holds only on the plasterboard will pull out at a load of 5 to 10kg. Less than a tenth the strength of DrylinePro™.

Failure Modes of Other Fixings

Standard Plugs / Rawlplugs

Standard expanding plugs are good but they do not work well in a dry lined wall. Here you can see a handrail that was installed on to a dry line wall using a traditional plastic plug. It failed after a few months of use.

Plasterboard Fracture

A standard expanding plug will tend to fracture the plasterboard rather than grip it. In any case, the plasterboard is not strong in axial load.

Plasterboard Failure

Drilling through the plasterboard and putting the standard expanding plug into the block wall behind will generate a strong fixing. The problem is that when the screw is tightened, the item being attached will crush the plasterboard into the wall and crack and damage it.

Self Drive Plasterboard Fixings

Self drive plasterboard fixings are good for light loads such as small pictures.

Plasterboard Fracture

These types of fixings that just grip in the plasterboard are great for the hanging light pictures on a dry line wall, but they will pull out quickly if any significant load is applied to them.