Wall Types and Fixings

There are many types of wall found in houses and choosing the correct fixing is vital if you want to safely hang something on it.

Building techniques have changed over the years with Lath and Plaster being found on most houses built before 1945. After World War 2, builders started to use solid block skimmed with plaster giving the appearance of Solid Walls. This period also saw the introduction of Stud Walls that continue to be used in modern houses. Houses built after 1990 are most likely to have been constructed using the Dry Lining technique.

Dry Lined Walls (1990-Present)

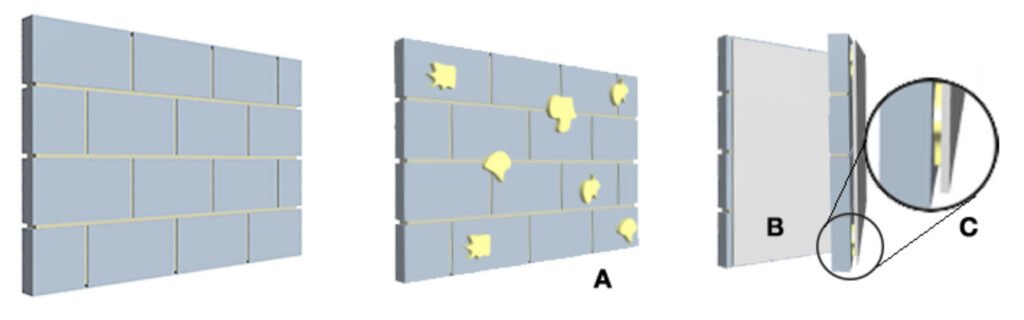

Although this method is quicker for the builder than traditional plastering, it creates a wall that is not compatible with standard wall plugs. The dry lining process starts with adding “dabs” of adhesive to the wall (A), then plasterboard is pressed onto the dabs (B). This quickly provides a smooth surface, however an awkward variable gap (C) is left between the plasterboard and the block work of the wall. The plasterboard is largely unsupported, and this creates the “hollow” sound if you tap the wall (unless you happen to tap over a “dab”).

Dry lined Wall Fixings

DryLinePro to the Rescue

Solid Walls

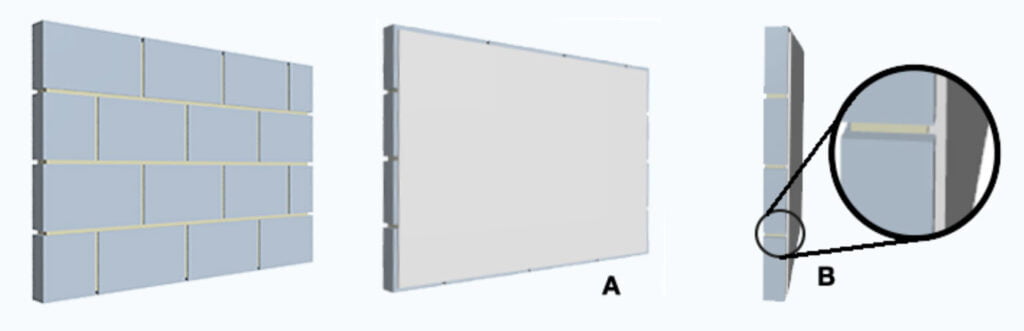

If your house or apartment walls have been finished with traditional plaster (A), then you have a solid wall with no gaps (B), and you can use traditional wall plugs or an expanding bolt to fix your TVs, shelves, curtain rails, radiators etc to the wall. Solid walls actually sound solid when you tap them. If they sound hollow when you tap the wall, you need to use a different type of fixing.

Solid Wall Fixings

Rawlplugs

Expanding Bolts

8mm Expanding bolt : Maximum pull out load 200kg+There was a significant increase in performance going to the larger bolt, although this does require a 13mm hole. The shear strength is excellent.Note that these bolts are not suitable for dry line walls as they do not support the plasterboard. They can be robustly fitted into the masonry wall behind the plasterboard, but if you then tighten down on them against the plasterboard, the plasterboard will fracture.

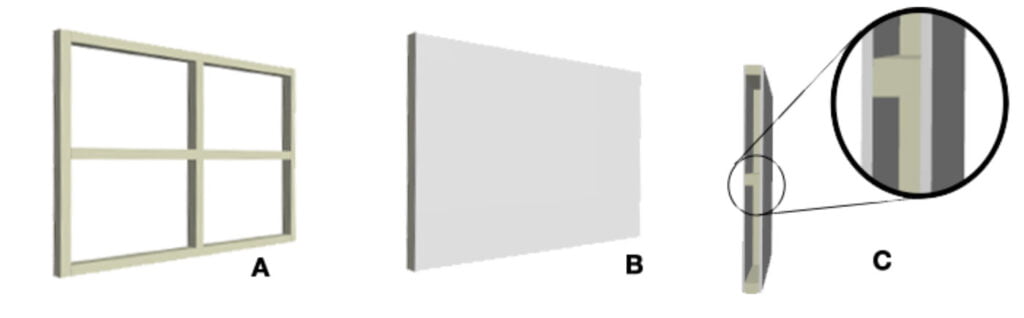

Stud Walls

Both solid walls and dry lined walls start with a block work wall. During the last 50 years, many internal walls have been based on a timber frame structure (A). Once the frame is covered with plasterboard (B) this type of wall is visually indistinguishable from the other types. This type of wall is known (in the UK) as a “stud wall”.

A stud wall, like a dry lined wall, will generally sound “hollow” when tapped apart from if you happen to tap over the wooden frame. You may be able to determine if your wall is a stud wall or dry line wall by tapping, but a quicker and more certain way is to drill a small hole where you need to put a fixing anyway, and see if there is a block work wall behind (dry line wall) or an empty cavity (stud wall). Stud wall fixings come in two types. Those that screw into the plasterboard and those that go through a hole in the plasterboard, and expand in some way behind the plasterboard within the cavity.